More Information

Submitted: October 19, 2023 | Approved: October 28, 2023 | Published: October 30, 2023

How to cite this article: Girish Kumar P, Dhanunjaya G, Venkateswar Rao K, Swain PC. Design and Development of a Dual-Volume Ionization Chamber for an Accident Monitor to Detect Gamma Radiation During Emergency Conditions in a Nuclear Reactor. Int J Phys Res Appl. 2023; 6: 189-193.

DOI: 10.29328/journal.ijpra.1001071

Copyright License: © 2023 Girish Kumar P, et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Keywords: Gamma ionization chamber; Gamma radiation; Accident monitoring; Nuclear power reactor

Design and Development of a Dual-Volume Ionization Chamber for an Accident Monitor to Detect Gamma Radiation During Emergency Conditions in a Nuclear Reactor

Girish Kumar Palvai*, G Dhanunjaya, K Venkateswar Rao and PC Swain

Electronics Corporation of India Limited, Radiation Detectors & Instrumentation Division, CSG, ECIL Post, Hyderabad, Telangana-500062, India

*Address for Correspondence: Girish Kumar Palvai, Electronics Corporation of India Limited, Radiation Detectors & Instrumentation Division, CSG, ECIL Post, Hyderabad, Telangana-500062, India, Email: e-mail: [email protected]

A Gamma Ionization Chamber was developed for the purpose of high gamma radiation detection during accident conditions in a Light Water reactor. The pre-eminence of the detector is that it was designed and developed to monitor gamma exposure rates in the wide range of 100 mR/hr to 107 R/hr. The detector has an overall diameter of 90 mm with a length of 400 mm. The response of the detector is accurate and the sensitivity is within ± 6% over gamma energies ranging from 660 KeV to 1.25 MeV.

The detector operates with a DC voltage of 500V. The V0.9 voltage is about 250V for 107 R/hr. The estimated operation life of the detector is about 20 years.

The emergency conditions in the Nuclear Power Reactor will result in a large gamma exposure rate in the containment areas. The magnitude of the gamma field is useful for determining post-accident conditions inside the area.

The accident conditions are severe and the monitoring of gamma radiation during that period requires a special design to withstand harsh environments like high temperature, pressure, high radiation dose and others.

The present study describes the performance of the design of the ion chamber which has qualified for ageing tests for an operational life of 20 years.

Design aspects of detector geometry

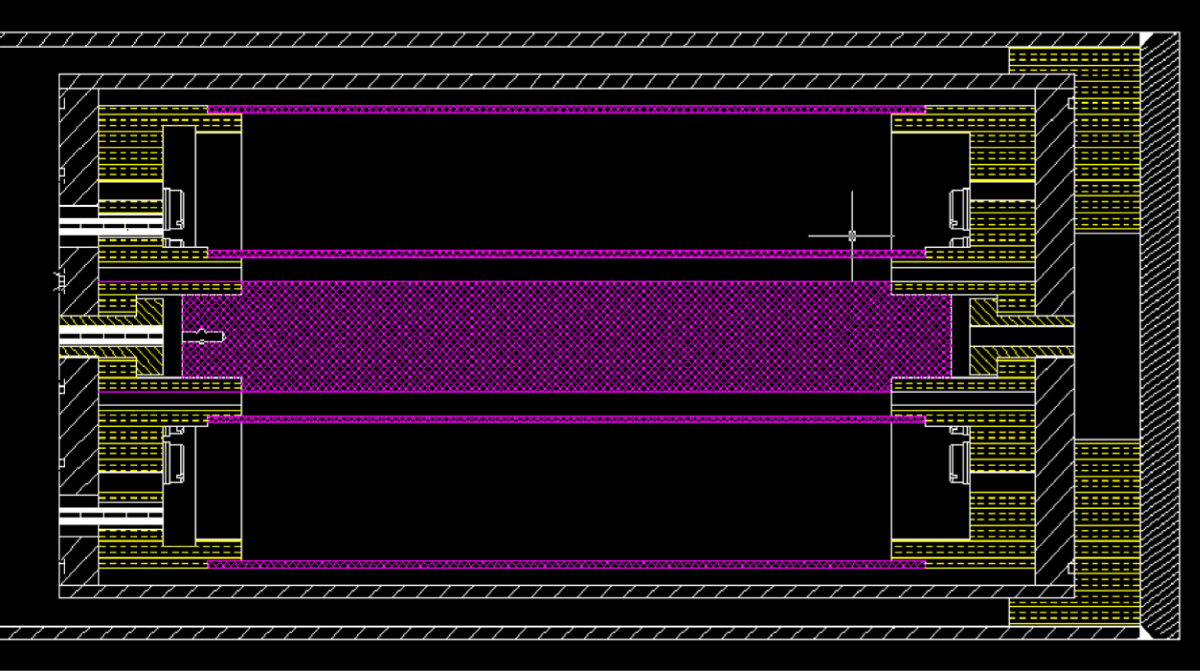

The detector has to detect a wide range of gamma radiation and hence, it was designed to have concentric dual-volume geometry with a common high-voltage electrode.

The ratio of “outer” to “inner” volumes and the ratio of “outer electrode gap” and “inner electrode gap” is put in a 10:1 ratio. The detector is filled with a combination of Argon and Nitrogen gas. The electrode gaps are chosen to have good charge collection efficiency even at the highest field detection.

Charge collection efficiency

The charge collection efficiency of the detector was calculated using the “Attix” formula [1]

Where ‘q’ is the charge to be liberated due to ‘X’ R/hr in units: esu/cc.sec; ‘d’ is inter-electrode gap; ‘V’ is applied voltage; ‘m’ is a constant ; m = 34.7 for Co-60.

To determine the charge collection efficiency at the highest field, the detector was tested with a Co-60 source at a food irradiation facility to a gamma exposure of 5x106 RAD/hr. The radioactive source is an arrangement of Co-60 line sources with an overall activity of about 1MCi. This field was determined by mapping the gamma field over the geometry of the detector using a calibrated in-core detector made for reactor instrumentation. The calibration uncertainty of this detector is ± 5%.

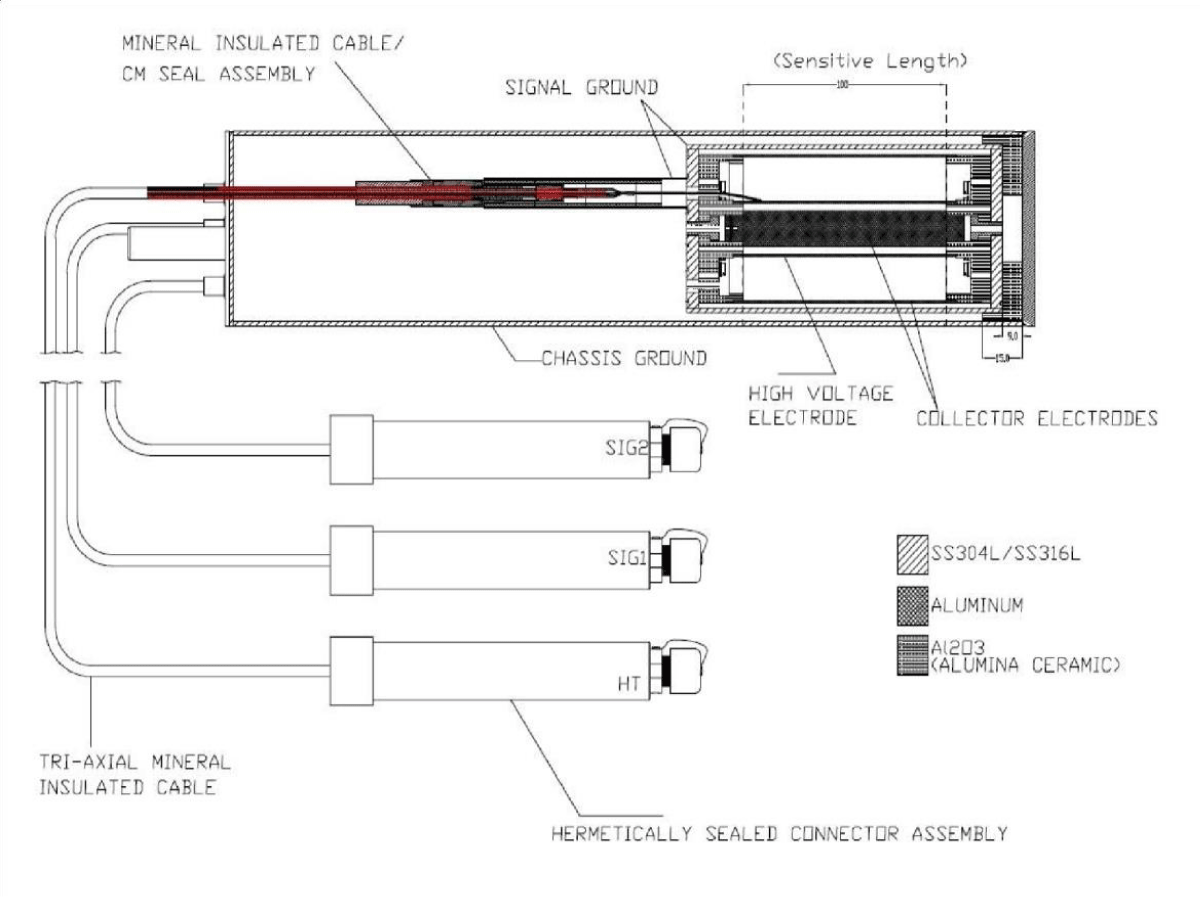

The detector was constructed in coaxial geometry having two electrically isolated gas gaps. The conceptual construction design is shown in Figures 1,2.

Figure 1: Conceptual Design of Ion Chamber.

Figure 2: Sensitive part of the detector.

The detector was made of Aluminum electrodes concentrically arranged in an SS304L tube. This tube was hermetically sealed in an SS316L shell, used as chassis ground.

The electrodes are isolated using highly pure Al2O3 ceramic discs. The electrical connections to the electrodes were derived out of casing using Ceramic to Metal seals.

Three tri-axial Mineral Insulated cables having copper conductors were used for providing high voltage and deriving two signals.

The inner electrode gap is 10 times less than the outer electrode gap.

A common electrode is used for providing Voltage for collecting the charge generated during ionization events in the two gas gaps.

The effective length of the detector is about 100 mm.

The outer casing (chassis tube) is hermetically sealed and integrated with three mineral-insulated triaxial cables to provide high voltage and derive signals.

These cables were terminated with PEEK-insulated miniature connectors having a continuous operating temperature of 200 oC and which could withstand a radiation dose of about 109 RAD.

The total geometry of the detector is filled with a gas mixture of Argon and Nitrogen.

Estimation of operation life

Thermal Ageing test & Radiation Ageing Tests were conducted on the detector to test the ageing effect on materials due to Temperature and Radiation seen by the detector in its service life time.

Arrhenius equation was used for determining the test duration of the ageing test at accelerated temperature.

Arrhenius equation is usually applied for polymers and thus applied to silicone gasket, considering it as the most vulnerable material in this design, to be affected by the temperature.

Arrhenius equation [2] was given by

Where,

‘E’ is the activation energy for the material under

‘K’ is Boltzman Constant i.e. 8.617x10-5 eV.K-1

‘t1’ is the ageing time required at accelerated temperature ‘T1’.

‘t2’ is the service lifetime at operating temperature ‘T2’.

‘T1’ is accelerated temperature

‘T2’ is the maximum operating temperature (60 °C)

The activation energy for the silicone gasket is considered as 1.07 eV.

‘t2’ is considered as 20 years for normal service period temperature, emergency conditions like “violation of heat” & “small leak” to work out the ‘t1’.

The ageing test time is worked out to be 8 days for an accelerated temperature of 135 oC for a service life of 20 years.

The thermal ageing test doesn’t show any “degradation of insulation materials” or “Ingress protection” by gaskets post-thermal ageing test.

Radiation ageing

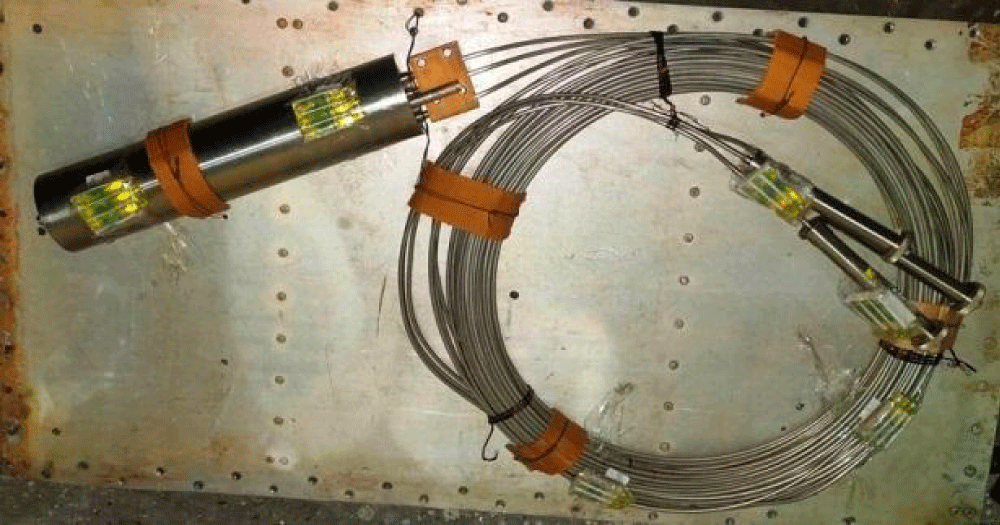

The detector was also exposed to Co-60 gamma field exposure in a food irradiation facility to a cumulative gamma Radiation dose of 10 MRad.

Regular dosimeters like DRDs could not record high dose values and thus chemical dosimeters were used for estimation of dose. Moreover, the gamma exposure will vary along the geometry of the detector, as the radioactive source utilised is the “line source” and not the “point source”. Hence, Chemical dosimeters (Ceric Cerous) were put at different locations on the detector as shown in Figure 3 for about 15 minutes to determine the dose incident on the different parts of the detector. The time of exposure was calculated by considering the average dose seen by connectors, cable & detector.

Figure 3: Detector arrangement for radiation ageing test.

There is a fall of insulation resistance by two decades from a level of 10 TOhm. However, the fall in insulation has not shown an effect on the performance of the detector.

The sensitivity of the detector was determined using a Cs-137 source, the field of which at the detector location is estimated by a standard absolute dosimeter.

The sensitivity of outer volume is found to be 25 pA/R/hr and inner volume is 2.3 pA/R/hr. The detection range for the first volume is 100 mR/hr to 104 R/hr and the second volume is 500 R/hr to 107 R/hr.

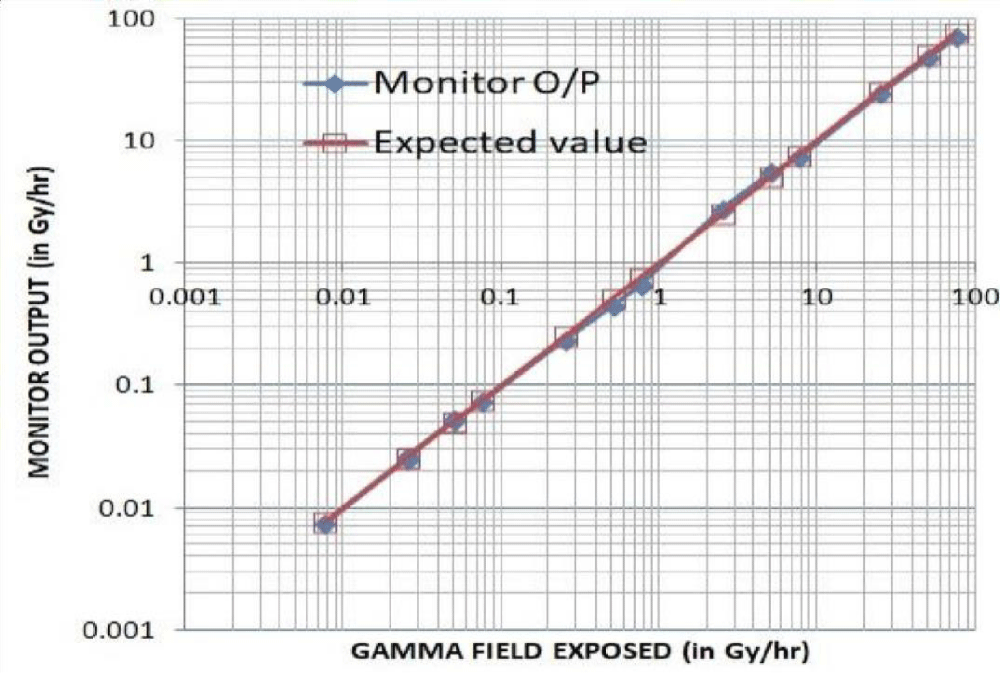

The detector was tested for linearity over the Gamma Field range of 100 mR/hr to 104 R/hr at standard Radiation Detectors Calibration facility (RSSD, BARC, India). The detector was tested at 3 points in each range decade. The relative intrinsic error is observed to be within ± 10% over this range. A monitor calibrated with a known current was used for the testing of this detector.

The linearity response [3] is obtained as shown in the Figure 4.

Figure 4: Linearity plot.

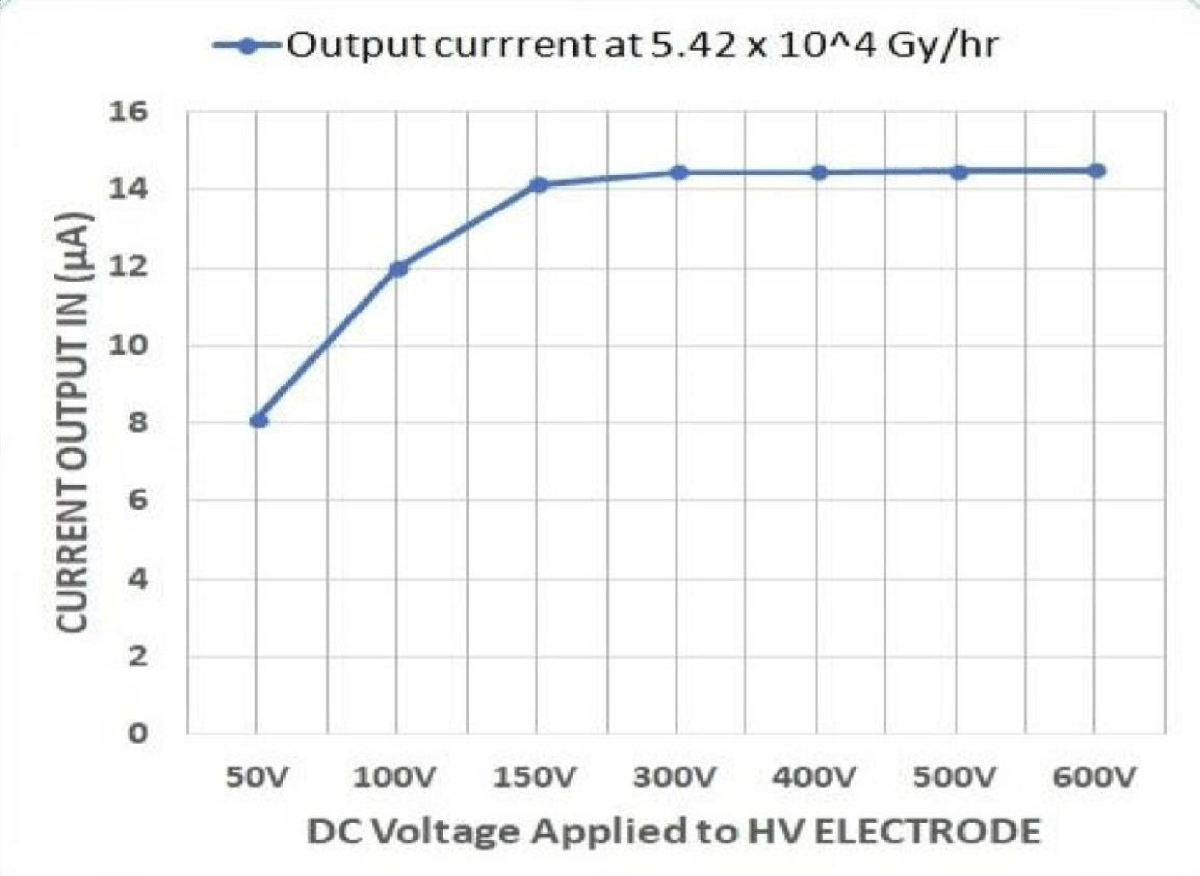

The detector was tested at a food irradiation facility for air kerma of about 5.4x104 Gy/hr (~6.3x106 RAD/hr) to ensure its operability to the highest specified gamma field. The V-I characteristic curve [3] for this test is shown in the Figure 5. This shows that the maximum collection efficiency of the detector is possible for a voltage around 150V which is very well within the operating voltage of 500 V DC.

Figure 5: Saturation characteristic plot.

The energy response of the detector was evaluated in the energy range of 100 KeV to 1250 KeV using X-rays of narrow beam qualities N-150, N-200, N-250, and Cs-137 & Co-60 radioactive sources.

The relative intrinsic error is observed to be within 10%.

The energy response requirement of the detector is in the range of 80 KeV to 8 MeV as per IEC 60951-3 with sensitivity within ± 30% [4]. The detector could be tested with gamma energies to 1.3 MeV only due to the limitation of the test facility.

To evaluate the energy response of the detector for higher gamma energies Montecarlo Simulation was used. Simulations were carried out with the Monte Carlo simulation method using MCNP4c2 for determining the energy response of the detector till energies 6MeV with N-16 isotope as reference [5-7].

The sensitivities for both volumes of the ion chamber were simulated. For the calculation of sensitivity (pA/mGy/hr), the knowledge of air KERMA at the centre of the detector volume is used. The air KERMA at point 100cm apart from the point source was evaluated using simulations by analytical method. The air kerma /photon at a point 100cm from the point source was also calculated using Monte Carlo simulations for various gamma energies and consistent with that calculated by analytical method. The response of the inner and outer chamber in terms of charge produced per photon or current produced per photon per second was evaluated with the aid of general-purpose Monte Carlo code MCNP4c2. The accident monitor ion chamber detector was simulated in MCNP using 50 surfaces, 28 cells, and involving 5 different materials. The F6:PE tally was used, which provides the energy deposited per unit mass (MeV/g) by gamma photons in both volumes.

The measured and simulated relative response (wrt Cs-137) of the detector is tabulated in Table 1.

| Table 1: Comparison between“Simulated” and “Measured data”. | |||

| Radioactive source/Radionuclide | Average Energy (MeV) | Simulated Relative Response (with respect to Cs-137) |

Measured Relative Response of the detectorwith respect to Cs-137 |

| X-Ray (N-120) | 0.1 | 0.87 | 0.80 |

| X-Ray(N-150) | 0.118 | 0.98 | 0.86 |

| X-Ray(N-200) | 0.164 | 1.03 | 0.90 |

| X-Ray(N-250) | 0.208 | 1.05 | 0.95 |

| Cs-137 | 0.662 | 1.00 | 1.0 |

| Co-60 | 1.25 | 1.01 | 1.02 |

| N-16 | 6.128 | 1.09 | |

The data shows that the simulated relative response of the detector is within 10% for 6 MeV gamma rays and thus the detector could measure gamma energies till 8 MeV with “Sensitivity” in acceptable limits as per IEC 60951-3.

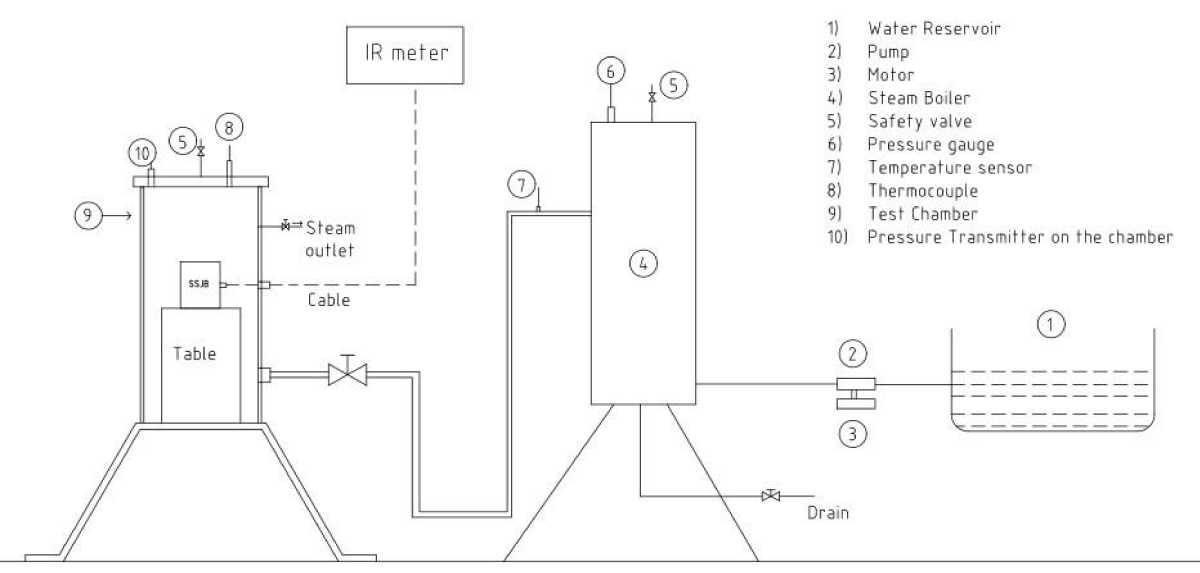

The detector was qualified for the Loss of Coolant Accident (LOCA) test by using a Steam Chamber. The chamber was qualified for Indian Boiler Regulations. The Detector was put in the steam chamber and subjected to a temperature of 150 °C ± 3 °C with a pressure of 0.49 Mpa ± 0.02 Mpa for a duration of 24 hours and then reduced linearly at a rate of 4 oC/hour till room temperature was achieved. The above profile is derived from the large leak emergency condition profile of the reactor. The test setup is shown in the Figure 6.

Figure 6: LOCA Test arrangement.

During the LOCA test, intermittently, insulation resistance was measured in between “HV” & “SIGNAL” electrodes with 500 V DC applied to the HV electrode. The leakage current was ensured to be within limits so as to not disturb the minimum detectable current when exposed to minimum gamma field i.e. 500 mR/hr.

Dual volume Ionization Chamber was designed and developed for use within the containment wall of Nuclear Reactors to monitor gamma radiation during the LOCA accident condition. The detector can withstand harsh emergency conditions and is designed to have a service life beyond 20 years.

The detector has passed the IP-67 protection test, vibration test, drop test, seismic test, thermal ageing test, radiation ageing, Loss of Coolant Accident (LOCA) & Air Crash test. The detector could measure the gamma radiation in the range of 100 mR/hr to 107 R/hr.

The detector has met most of the conditions/specifications mentioned in IEC 60951-3, “Nuclear Power Plants – Radiation Monitoring for Accident & Post Accident conditions; Equipment for continuous high range area gamma monitoring” and thus, this paper will help the designers of the Gamma Radiation Monitor for Accident Conditions like LOCA (emergency small leak, large leak etc) in Nuclear Reactor.

We thank RSSD, and BARC for extending support in the analysis of the detector for energy response using Monte Carlo Simulation Software.

We thank Sri Karra Srinivas & Smt Archana of RID, ECIL for providing the required Monitor Instrumentation to evaluate the detector performance.

I convey my deep gratitude to Mr. Anurag Kumar, Managing Director of our organization for his patronage.

Funding data

We gratefully acknowledge the funding provided by M/s Nuclear Power Corporation of India Limited for carrying out this work and related studies.

- Attix FA. Introduction to Radiological Physics and Radiation Dosimetry.

- Rodríguez-Prieto A, Callejas M, Primera E, Camacho AM. Reliability and Thermal Ageing of Polymers intended to severe Operating Conditions. 2021; 69: 9.

- Alex M, Prasad KR. Ion Chamber for High Range Gamma Measurement in space critical application. Journal of Scientific & Industrial Research. 2001; 60: 35-39.

- IEC 60951-3, Nuclear Power Plants – Radiation Monitoring for Accident & Post Accident conditions; Equipment for continuous high range area gamma monitoring.

- Kim JC, Kim JK, Kim YK, Park SH. Analysis of Design Characteristics of Cylindrical Ion Chamber made by KAERI. A Comparison between EGSnrc, MCNP and experiment. Journal of Nuclear Science and Technology. https://doi.org/10.1080/00223131.2004.10875705

- Pibida L, Minniti R, McCord M. Characterization Method of Ionization Chamber Type Detectors; NIST Technical Note 2204. https://doi.org/10.6028/NIST.TN.2204

- Kim HS, Park SH, Ha JH, Kim YK, Kim JK, Cho SY, Kim DH, Ching EK. Operational Characteristics of Ionization Chambers for a Radiation Monitoring. Journal of Nuclear Science and Technology. https://doi.org/10.1080/00223131.2008.10875870